The factory floor isn’t what it used to be. Imagine a world where machines talk to clouds, quality control cameras spot defects faster than seasoned inspectors, and energy systems learn to optimize themselves. This isn’t science fiction — it’s 2025’s manufacturing reality, powered by cloud computing. Let’s unpack five game-changing implementations rewriting industry rulebooks.

1. 3M’s Digital Materials Hub (Think: Netflix for Engineers) 3M just launched a cloud-based library where engineers binge-watch material data like others stream shows. Hosted on AWS, this digital hub offers instant access to 3M’s material specs, simulation data, and testing reports — cutting design times from weeks to hours. It’s like having a materials scientist in your back pocket, helping teams avoid costly trial-and-error in product development.

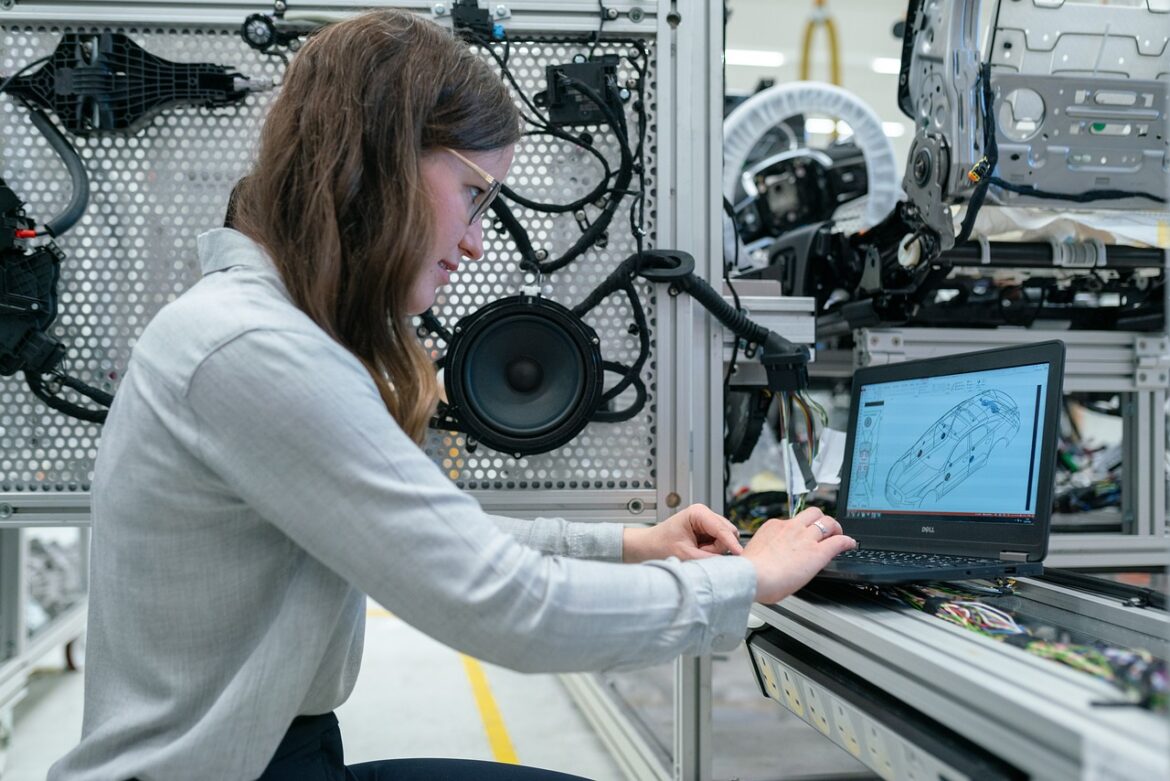

2. Rockwell Automation + AWS: The OT/IT Power Couple Rockwell’s factory robots now speak fluent cloud. Their collaboration with AWS merges industrial machines with cloud analytics, creating factories that self-diagnose production issues. Early users report fewer unplanned downtime incidents thanks to real-time equipment health monitoring. It’s like giving machines a Fitbit that predicts breakdowns before they happen.

3. Infor’s AI-Powered Warehouse Brain Infor’s cloud-native warehouse management system now includes a GenAI assistant that plans labor shifts and predicts inventory needs. One logistics company slashed overtime costs by 18% using its predictive staffing features. The system treats every forklift driver and autonomous robot as interchangeable

References:

- https://www2.deloitte.com/us/en/insights/industry/manufacturing/2025-smart-manufacturing-survey.html

- https://logisticsviewpoints.com/2025/05/01/infor-analyst-innovation-summit-2025-a-look-at-the-future-of-industry-cloud/

- https://aws.amazon.com/blogs/industries/how-aws-is-transforming-manufacturing-key-takeaways-and-insights-from-hannover-messe-2025/

- https://chiefexecutive.net/2025-tech-industry-trends-global-business-outlook/

- https://tech-stack.com/blog/how-machine-learning-is-improving-manufacturing/

- https://techcrunch.com/2025/05/01/chatgpt-everything-to-know-about-the-ai-chatbot/

- https://azure.microsoft.com/en-us/blog/adaptability-by-design-unifying-cloud-and-edge-infrastructure-trends/

- https://news.ppg.com/press-releases/default.aspx