Imagine walking into a factory where machines almost think for themselves, sensors talk, and invisible tech wizards are constantly working behind the scenes. This isn’t science fiction—it’s digital transformation happening right now, and hardware is stepping into the spotlight. Let’s look at five of the hottest hardware trends making real-life waves—in ways that even a non-techie can understand and appreciate.

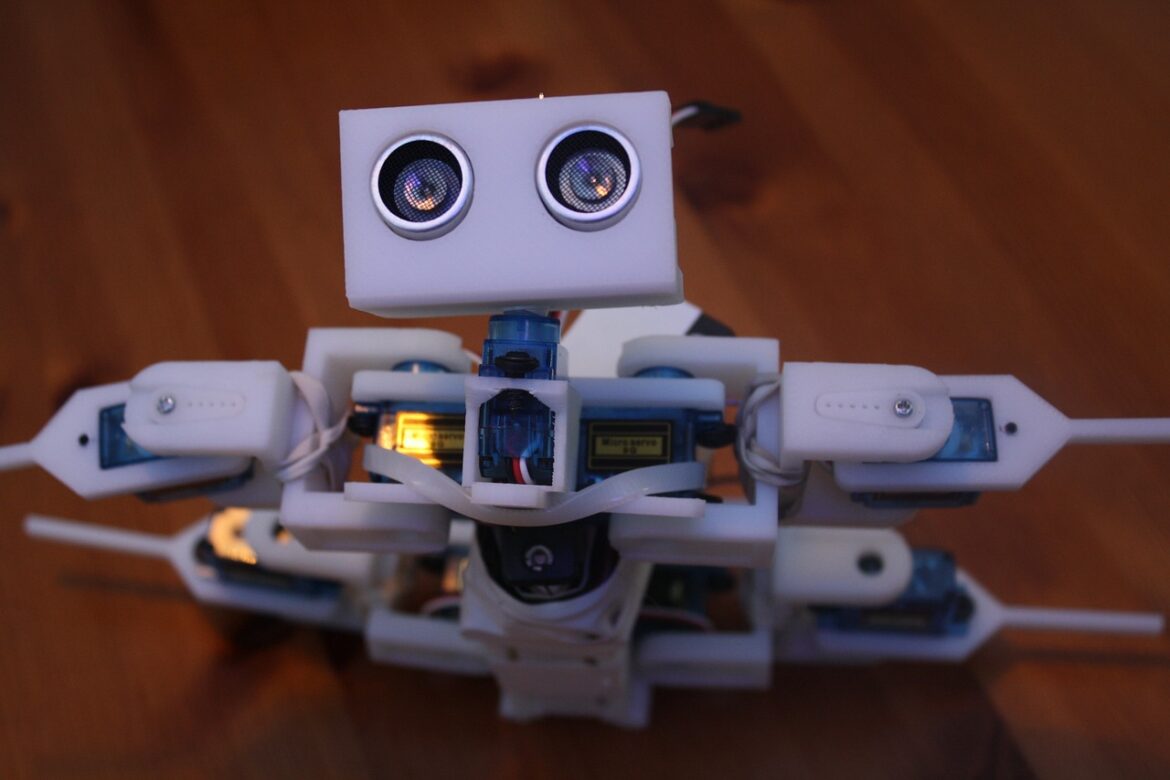

Smart Factory Automation Hardware Factories are getting a serious brain upgrade. Automation hardware—think robots, robotic arms, and conveyor systems—is now everywhere. Take a car manufacturer in Detroit, for example, where robots work alongside humans, welding parts with precision and speed. The result? Production is up by 10–20%, and workers can focus on tasks that truly need a human touch. Companies are pouring real money into these technologies, with automation hardware soaking up 41% of smart manufacturing budgets. This is the backbone of the smart factory wave, where less manual labor and fewer mistakes mean more output and happier workers.

Edge Computing Devices Edge computing is like having tiny data centers right where the action is. Instead of sending every bit of data to a remote server, edge devices process it locally—in machines, on the shop floor, or even in your local store. A delivery company using AI-powered cameras in distribution centers is a real-world example: the cameras spot package sorting errors on the spot, reducing mishaps and keeping logistics smooth. These devices are energy-efficient and sensitive to privacy, making them perfect for places where speed and security matter.

5G-Enabled Hardware Faster, stronger, everywhere—that’s the promise of 5G-enabled devices. Imagine a construction site where drones are streaming live video to managers miles away, or a port where autonomous vehicles are loaded and unloaded in real-time using a 5G network. Companies are investing in hardware that can tap into this supercharged connectivity, opening doors for advanced robotics, augmented reality training, and real-time remote support. When communication and data crunching happen at lightning speed, everyone saves time.

Advanced AR Glasses and Wearables Remember when glasses were just for seeing better? Now, AR (augmented reality) glasses like Google’s and Microsoft’s HoloLens are popping up in factories and warehouses, where digital instructions float in front of workers’ eyes, guiding them step-by-step. A real-life story from a German engineering firm shows field technicians troubleshooting machines with digital overlays, reducing errors and training times. These wearable gadgets are lightweight, battery-smart, and packed with sensors, making everyday work a little bit like living in the future.

Industrial IoT Sensors Sensors—those tiny, unassuming gizmos—are the unsung heroes of digital transformation. In a chocolate factory, sensors detect temperature changes before chocolate burns, ensuring every bar tastes perfect. In logistics, they track shipments in real time, letting warehouses and consumers know exactly where their orders are. Almost half of manufacturing firms now use these sensors to collect data, predict maintenance needs, and keep their operations humming.

These hardware trends aren’t just about fancy gadgets—they’re making real differences, day by day, in how companies compete, how workers get more done, and how products get to your doorstep faster.

References:

- https://www.simplilearn.com/top-technology-trends-and-jobs-article

- https://fourjaw.com/blog/smart-manufacturing-trends-in-2025-fourjaw

- https://news.networktigers.com/hardware-hub/edge-computing-hardware-trends-2025/

- https://kaopiz.com/en/articles/cutting-edge-technology/

- https://www.industryweek.com/technology-and-iiot/podcast/55296654/podcast-hardware-advances-driving-manufacturing-digital-transformations

- https://www.cambridgemc.com/dealing-with-disruptive-trends-how-to-ensure-your-strategy-remains-relevant-in-a-period-of-accelerating-change

- https://www.techinsights.com/blog/five-key-trends-power-semiconductors-2025

- https://theologiaviatorum.org/index.php/tv/pages/view/submission-guidelines